The Production Advantage of GNSS Machine Control in Earthwork (and How to Actually Capture It)

Earthwork is a production game. The faster you can move material to the correct elevation and slope—without rework, without chasing grade stakes, without burning time on “check it again”—the more margin you protect.

That’s the core advantage of GNSS machine control: it turns grade from a constant conversation into a constant reference. Instead of relying on stakes, paint, and radio calls to translate a plan into motion, the operator has a live design target in the cab. When the model and site control are solid, machines work smoother, grade is hit sooner, and the entire jobsite runs with fewer interruptions.

But here’s the part most people miss: GNSS machine control doesn’t automatically create production. It removes bottlenecks—and your crew captures the savings only if the model is clean, the control is tight, and the workflow is set up to avoid the usual failure points.

This post breaks down where the production gains really come from, where contractors lose them, and how to make machine control pay you back on real jobs.

What “Production Advantage” Actually Means in Earthwork

Production isn’t just yards-per-hour. It’s:

- Fewer passes to reach final grade

- Less downtime waiting on layout/checks

- Less overcut/overfill, which reduces imported material and disposal

- Less rework, especially on subgrade and finish trim

- Faster decision-making when plans change or RFIs land

- Greater consistency across operators, shifts, and machines

GNSS machine control touches all of those. The biggest gains usually come from the stuff that’s hard to see on a daily report: the little stoppages, the rechecks, the “we trimmed it but it’s still off,” the undercut that wasn’t supposed to happen, the pad that ends up low because control drifted and nobody caught it until the proofroll.

The Real Bottleneck: Information, Not Iron

Most grading delays come from one of two things:

- The target isn’t clear (or changes constantly).

- The target is clear, but it’s not at the point of action (the cab).

Traditional staking and checking is a translation system:

- Engineer’s plan → survey interpretation → stakes/offsets → operator interpretation → grade checker verification → correction pass

Every handoff is a chance for delay and error.

GNSS machine control shortens that chain:

- Design model + control → machine guidance → verification

You still need layout and checking—especially on high-risk items—but the machine is no longer blind between spot checks.

Where the Time Savings Come From (On Real Crews)

1) Fewer “Stop the Machine” Moments

Every time an operator pauses to ask, confirm, wait, or double-check, production bleeds out. Machine control reduces:

- Waiting on grade setters

- Waiting on layout to come back to an area

- Guessing slopes and checking them after the fact

- Overbuilding “just to be safe” and then trimming it down later

Even if each pause is only 3–5 minutes, they stack up into hours across a week and across multiple machines.

2) Fewer Passes to Hit Tolerance

Without guidance, operators often “sneak up” on grade:

- Cut a bit, check, cut a bit, check, correct slope, check again

With GNSS targets visible, operators can converge faster:

- The machine is guided toward the correct plane/surface continuously, so the approach becomes smoother and more direct.

This matters most on:

- Subgrade

- Building pads

- Parking lots

- Pond bottoms/berms

- Long slopes and tie-ins

- Road subbase/base layers

3) Reduced Overcut and Overfill

Overcut and overfill don’t just cost material. They cost:

- Haul cycles

- Dozer time

- Compaction effort

- Proofroll failures

- Schedule risk

When the cab has a reliable design surface, operators are less likely to “dig insurance” or “leave it high everywhere.” That translates into cleaner material movement and fewer surprises for the next crew.

4) Smoother Workflow for Foremen and Supers

Foremen lose time when they’re forced into constant micromanagement:

- “Go another two tenths.”

- “That slope looks steep.”

- “We’re low over there. Fix it.”

GNSS machine control pushes some of that mental load back to the system—assuming the system is right.

Result:

- The foreman can manage sequencing, not babysit every elevation decision.

5) Faster Response to Plan Changes

Plan revisions, addenda, and RFIs are unavoidable. With traditional staking, changes can create a chain reaction:

- restake → recheck offsets → move stakes → re-explain → redo area

With a model-driven workflow:

- update surface → reload model → proceed with confidence

That becomes a major advantage when deadlines are tight and changes land late.

Where GNSS Machine Control Pays Off the Most

Not every task produces the same return. These are the “high leverage” areas:

Mass Grading + Balance

If your site has significant cut/fill, machine control helps you:

- maintain target elevations by phase

- keep haul routes and dumps aligned with the plan

- avoid “digging a hole you didn’t mean to” that throws balance off

Subgrade (The Money Layer)

Subgrade is where small errors become expensive:

- undercut expands

- base thickness changes

- proofroll failures multiply

- drainage issues show up later

Machine control shines here because it helps prevent the kind of “close enough” grading that turns into rework when the proofroller or inspector arrives.

Pads, Parking Lots, and Large Flatwork Prep

Big flat areas are deceptively tricky:

- small slope errors cause ponding

- low spots get found at the worst time

- tie-ins drift over distance

Machine control gives continuous slope/elevation feedback.

Ditches, Swales, Slopes, Berms, and Ponds

These are areas where shape matters:

- slopes must tie correctly

- inverts must flow

- ponds must drain to structures

- berms must meet specs

Machine control makes it easier to maintain consistent geometry—especially when the crew is moving fast.

The #1 Production Killer: “Bad Model, Good Equipment”

The industry has learned this the hard way: the machine can only be as accurate as the model and control behind it.

The most common problems that destroy the expected production advantage:

- Surfaces missing breaklines, leaving “soft” grade transitions

- Wrong elevations due to datum mix-ups or bad benchmarks

- Vague or inconsistent design intent (plan sheets don’t match details)

- Boundaries not defined (machines chase grade outside limits)

- Control points that don’t match the model coordinate system

- Calibration errors that no one validates until it’s too late

When this happens, crews lose trust in guidance, and the job goes right back to “stake and guess”—except now you’re paying for machine control and not benefiting from it.

A Practical Workflow That Captures the Advantage

Here’s a clean, repeatable approach (the kind TerraPrecision Solutions builds around):

Step 1: Confirm Control, Datum, and Intent

Before modeling:

- Identify site datum and vertical reference

- Confirm coordinate system (state plane, grid/local)

- Verify benchmarks and any known control points

- Clarify design intent if plan sheets conflict

Goal: eliminate preventable surprises early.

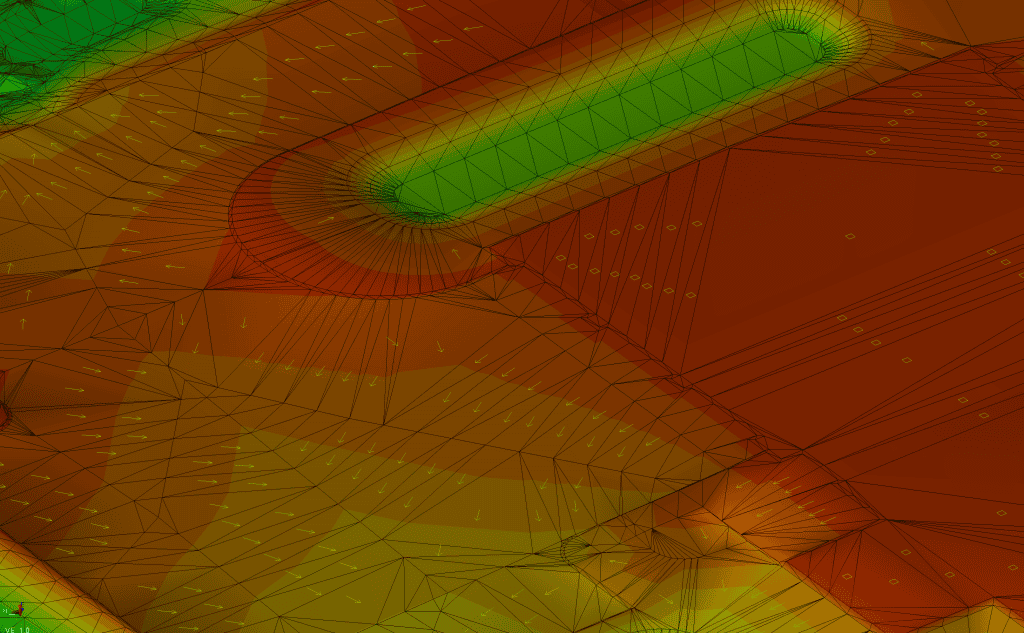

Step 2: Build Surfaces That Match How Operators Actually Work

A good machine surface:

- includes all critical breaklines

- avoids awkward triangulation that “waves” grade

- reflects real sequence (strip, subgrade, base, finish)

- defines working limits so operators don’t chase grade in the wrong areas

- includes clean transitions and tie-ins

Goal: create a surface that gives stable guidance and confidence in the cab.

Step 3: Deliver Field-Ready Files (Not Just “A Model”)

A production-ready deliverable package typically includes:

- existing ground surface (for reference)

- design surfaces by phase/layer

- linework (edges, curb returns, ditch centerline, etc.)

- points as needed (structure inverts, rims, key hubs)

- a simple naming convention operators can understand

Goal: reduce confusion and keep machines pointed at the right target.

Step 4: Calibration + Validation (Non-Negotiable)

Before running full production:

- calibrate machine properly

- verify against known points/hubs

- cut a small test area and check it

- confirm the guidance matches expected elevations/slopes

Goal: earn trust early so the crew leans on the system instead of second-guessing it.

Step 5: Use Spot Checks as Quality Control (Not as the Primary Driver)

Even with machine control, good crews still check:

- critical elevations

- tie-in transitions

- drainage inverts

- first-run areas for each phase

The difference is: checks become verification, not navigation.

Goal: keep quality high without slowing production.

What “Responsibly Using Machine Control” Looks Like

If you had to sum it up in one line:

Use GNSS machine control to run production—use layout/checking to manage risk.

That means:

- Do not blindly trust guidance on day one

- Do not skip control verification

- Do not assume all designs are “model-ready”

- Do not treat the model as static if addenda are flying

It also means:

- Operators should be trained on what they’re seeing

- Foremen should know which surface is active and why

- Survey/layout should be aligned with the same coordinates and datum

This is where the “technology” becomes a system, not a gadget.

Common Questions (and Honest Answers)

“Can we cut survey costs with machine control?”

Sometimes—you can reduce repetitive staking and some grade-setting labor. But most contractors find the real win is not “no survey,” it’s less waiting and less rework.

“Does it work under trees or near buildings?”

GNSS accuracy can be affected by canopy, obstructions, multipath, and site conditions. In those areas:

- you may rely more on total station / UTS

- you may shift workflows

- you may increase spot checks

Machine control still helps, but the plan needs to acknowledge limitations.

“Is it worth it on smaller jobs?”

It can be—especially if:

- there are multiple phases or revisions

- tolerances matter

- the crew is tight on schedule

- rework risk is high (subgrade, drainage, large pads)

A Simple ROI Example (How Contractors Actually Think About It)

Let’s keep this practical and conservative.

Assume:

- 1 dozer + 1 excavator + 2 trucks operating for grading phases

- machine control reduces rework and downtime enough to save 1–2 hours per day across the spread (not per machine)

- that’s 5–10 hours/week

- over a multi-week earthwork scope, the saved hours quickly become meaningful

But the bigger money is often in:

- avoiding imported material due to overcut

- preventing base thickness changes from low subgrade

- preventing drainage regrade because slopes didn’t hold

- eliminating “final week panic” where everyone is trimming and checking non-stop

If machine control helps you avoid even one major rework event on subgrade or drainage, it can pay for modeling and support many times over.

The Difference Between “We Have Machine Control” and “We Run Machine Control”

You’ll see two types of sites:

Sites that own machine control

- Equipment has screens and receivers

- Files are inconsistent or unclear

- Operators don’t trust the model

- Foreman still runs everything off stakes and spot checks

Result: minimal production gain.

Sites that run machine control

- Clean surfaces by phase

- Control is verified

- Operators know which surface they’re on

- Foreman uses models to plan sequence

- Checks validate, not guide

Result: real production advantage.

The gap between these two is not the equipment—it’s the workflow and file quality.

What TerraPrecision Solutions Does (and Why It Matters)

At TerraPrecision Solutions, we focus on the part that makes or breaks the benefit: model quality and field-ready deliverables.

If you want the production advantage of GNSS machine control, you need:

- surfaces that behave correctly in the cab

- clean breaklines and transitions

- proper control alignment

- phase-based files that match how the job will actually be built

- fast support when revisions arrive

That’s the difference between “we tried it” and “we wouldn’t go back.”

What to Send Us to Get Started

If you want a quick turnaround quote and a clean setup, send:

- plan set PDF (latest)

- any CAD files (if available)

- control notes / coordinate system info

- benchmark info (vertical datum)

- machine type and system (Trimble/Topcon/etc.)

- what you need modeled (subgrade, base, finish, pond, road, etc.)

- schedule: when you need first files and when revisions are likely

Even if you don’t have everything, send what you have—we’ll tell you what’s missing and how to handle it.

Closing: The Advantage Is Real—If You Build the Foundation

GNSS machine control can absolutely increase production in earthwork and excavation. The gains show up in fewer passes, fewer interruptions, less rework, and smoother sequencing.

But the technology only pays when:

- the model is built correctly

- the control is verified

- the crew trusts what’s in the cab

- checks are used to manage risk, not to do basic navigation

Do that, and machine control becomes what it was always supposed to be: a system that keeps iron moving and grade correct—at the same time.